Relays are electromechanical devices used in electrical circuits to switch high-power loads or signal circuits using a low-power input. They consist of a coil and one or more sets of contacts, which open or close when the coil is energized or de-energized. Here is an overview of relays:

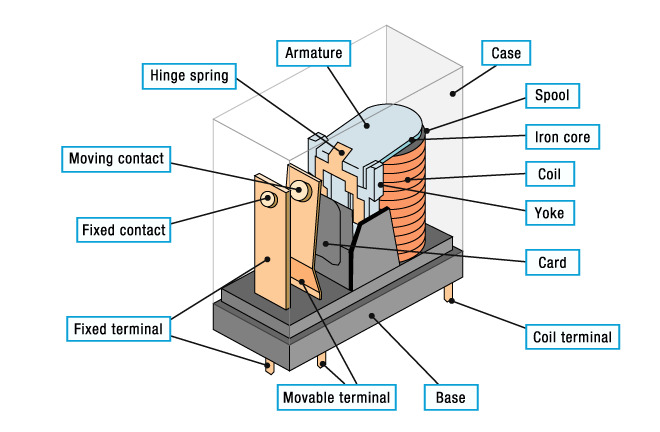

Components of a Relay:

-

Coil: The coil is the electromagnet that generates a magnetic field when current flows through it, causing the contacts to move.

-

Contacts: These are switch-like components that are either normally open (NO), normally closed (NC), or change over (CO) contacts. They control the connection between the relay input and the output.

-

Armature: The moving part of the relay that is attracted to the coil when it is energized.

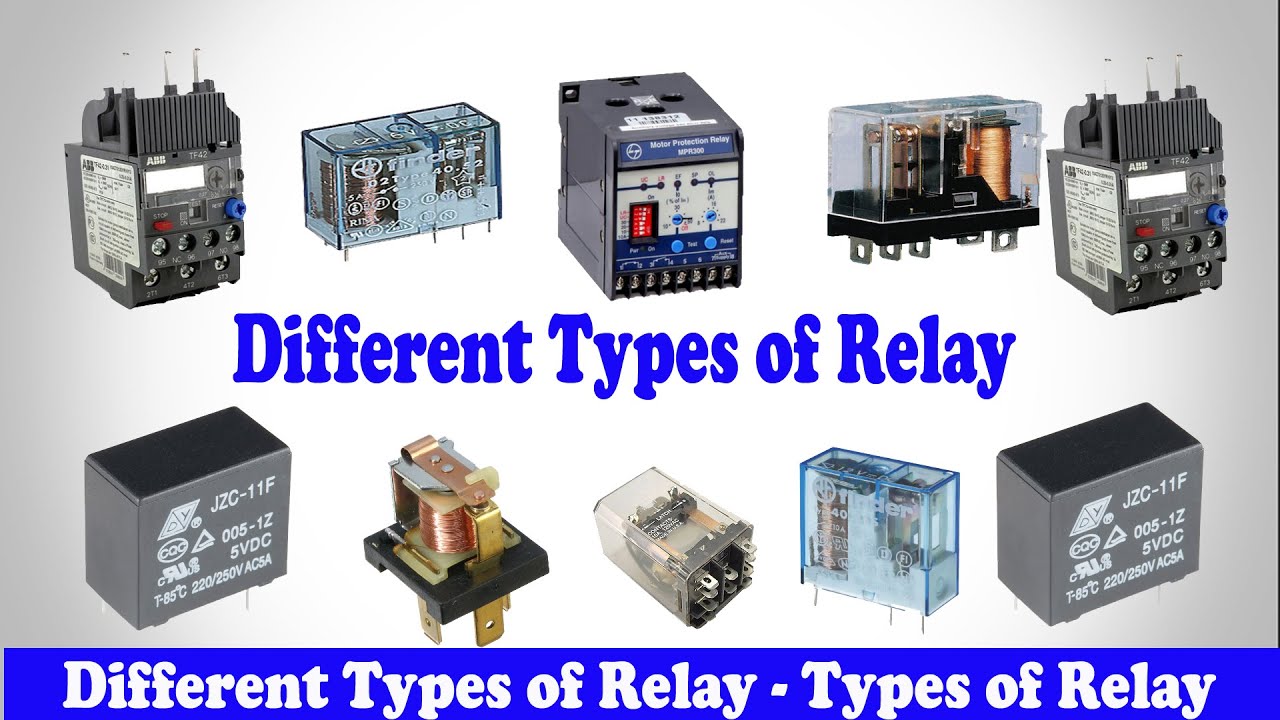

Types of Relays:

-

Electromechanical Relays: These are the traditional relays that use electromagnetic coils to control the contacts.

-

Solid-State Relays (SSRs): SSRs use semiconductors to perform the switching operation, offering advantages like faster switching speed and longer lifespan compared to electromechanical relays.

-

Reed Relays: These relays use reed switches as the contacts and are commonly used in low-power, high-speed applications.

-

Latching Relays: These relays maintain their state (either open or closed) even when the input power is removed, making them suitable for power-saving applications.

Applications of Relays:

-

Industrial Automation: Used for controlling motors, heaters, and other high-power devices in industrial settings.

-

Automotive Industry: Relays are used in automotive applications for controlling lights, fans, and other electrical systems.

-

HVAC Systems: Heating, ventilation, and air conditioning systems use relays to control motors and compressors.

-

Telecommunications: Relays are used for signal routing and switching in telecommunication networks.

Working Principle:

-

When current flows through the coil, it generates a magnetic field that attracts the armature, causing the contacts to change position.

-

Depending on the type of relay, the contacts will switch between the NO, NC, or CO positions to open or close the circuit.

Relays are essential components in control systems where low-power control signals need to switch high-power loads. They offer isolation between control circuits and load circuits, protecting control circuitry from high voltages and currents. If you have more specific questions about relays or need additional information, feel free to ask!

Classified by working principle

Relays can be classified into various types based on their working principles and how they function. Here are some common classifications of relays based on their working principles:

1. Electromechanical Relays:

- Operation: These relays use an electromagnet to mechanically operate the switch contacts.

- Working Principle: When the coil is energized, it creates a magnetic field that moves an armature to open or close the contacts.

- Applications: Widely used in industrial control systems, automotive applications, and power systems.

2. Solid-State Relays (SSRs):

- Operation: SSRs use semiconductor devices like thyristors or transistors to perform switching without any moving parts.

- Working Principle: Control signals trigger the semiconductor to switch the load circuit without the need for physical contacts.

- Advantages: Faster switching speeds, longer lifespan, and reduced electromagnetic interference compared to electromechanical relays.

- Applications: Used in applications where silent operation, long-term reliability, and fast switching speeds are required, such as in industrial automation, HVAC systems, and medical equipment.

3. Reed Relays:

- Operation: Reed relays use magnetic reeds as part of the switching mechanism.

- Working Principle: When a magnetic field is applied to the reed switch, it closes the contacts to complete the circuit.

- Advantages: Smaller size, faster switching speeds, and longer operational life compared to some other types of relays.

- Applications: Commonly used in telecommunications, automatic test equipment, and low-power applications.

4. Polarized Relays:

- Operation: Polarized relays rely on the polarity of the applied voltage to control the switching operation.

- Working Principle: The coil's windings are asymmetric, allowing the relay to operate in a specific direction.

- Applications: Used in applications where the direction of the current or voltage is critical for proper operation.

5. Hybrid Relays:

- Operation: Hybrid relays combine the features of electromechanical and solid-state relays in one device.

- Working Principle: They use electromechanical components for switching high-current loads and solid-state devices for control logic.

- Advantages: Offer the benefits of both types of relays, combining high switching capacity with fast response times.

- Applications: Suitable for applications that require both the high power-handling capability of electromechanical relays and the speed and reliability of solid-state relays.

These classifications cover some of the most common types of relays based on their working principles. Selecting the right type of relay for a specific application depends on factors such as switching speed, power-handling capabilities, reliability requirements, and environmental conditions.

Classified by the nature of the input signal

Relays can also be classified based on the nature of the input signal they receive. Here are some common classifications of relays based on the nature of the input signal:

1. Electromechanical Relays:

- Low-Level Signal Relays: These relays are designed to operate with low-level control signals, typically in the range of millivolts to a few volts.

- High-Level Signal Relays: High-level signal relays can operate with control signals at higher voltage levels, which may range from a few volts to tens of volts.

2. Solid-State Relays (SSRs):

- AC Input SSRs: These relays are designed to operate with AC control signals, typically for applications where AC power control is required.

- DC Input SSRs: DC input SSRs are used with DC control signals, providing a solid-state switching solution for DC circuits.

3. Digital Input Relays:

- Binary Input Relays: These relays respond to binary signals, such as logic level "high" or "low" signals (1 or 0), to switch their contacts.

- Pulse Input Relays: Pulse input relays respond to pulse signals of varying durations or frequencies to trigger the switching action.

4. Analog Input Relays:

- Voltage-Controlled Relays: These relays switch based on the voltage level of the input signal, often used in applications where voltage variations need to be detected.

- Current-Controlled Relays: Current-controlled relays operate based on the current level of the input signal, commonly used in current sensing and control applications.

5. Frequency-Controlled Relays:

- Frequency-Triggered Relays: These relays switch based on the frequency of the input signal, useful in applications where frequency variations are critical for operation.

6. Temperature-Controlled Relays:

- Thermal-Relays: Used in applications where the input signal is the temperature, triggering the relay's action based on temperature thresholds.

7. Time-Delay Relays:

- Delay-On/Off Relays: These relays are triggered by a signal, but they have a built-in time delay before switching the contacts on or off.

- Interval Timers: Interval timers trigger the relay to switch the contacts based on predefined time intervals.

Relays designed for specific input signals can provide precise control and automation in various applications. Selecting the right type of relay based on the nature of the input signal is crucial for ensuring proper operation and reliability in the intended application.

Classified by relay contact load

Relays can also be classified based on the load they are designed to switch or control. Here are some common classifications of relays based on the contact load they can handle:

1. General-Purpose Relays:

- Low-Current Relays: These relays are designed to switch or control low-current loads, typically up to a few amperes.

- Medium-Current Relays: Suitable for switching medium-current loads, typically in the range of a few amperes to tens of amperes.

- High-Current Relays: Designed for high-current applications, capable of switching loads ranging from tens of amperes to hundreds of amperes.

2. Signal Relays:

- Low-Power Signal Relays: Used for switching signals or control circuits with low power requirements, usually in the milliwatt range.

- High-Frequency Signal Relays: Designed for high-frequency signal switching applications, providing stable performance at high frequencies.

3. Power Relays:

- Low-Power Control Relays: These relays control low-power loads such as lights, fans, and small motors.

- High-Power Control Relays: Used for switching high-power loads such as large motors, heaters, and industrial equipment.

4. High Voltage Relays:

- Low-Voltage Relays: Designed to switch low-voltage loads safely and reliably.

- High-Voltage Relays: Built to withstand and switch high-voltage loads, providing isolation and protection.

5. High-Frequency Relays:

- Radio Frequency (RF) Relays: Designed for radio frequency applications where signal integrity and minimal signal loss are critical.

- Microwave Relays: Specifically built for microwave applications, offering low insertion loss and high isolation at microwave frequencies.

6. Motor Control Relays:

- Single-Phase Relays: Used for controlling single-phase motors in appliances and industrial equipment.

- Three-Phase Relays: Designed for the control and protection of three-phase motors, commonly used in industrial applications.

7. Latching Relays:

- Unlatching Relays: These relays require continuous power to maintain the switched state and return to the default state when power is removed.

- Bi-Stable Latching Relays: Maintain their switched state even when power is removed, reducing power consumption and suitable for power-saving applications.

Relay selection based on the type of load is crucial to ensure the relay can handle the expected current, voltage, and power requirements of the application. Using the appropriate relay for the specific load helps ensure efficient and reliable operation of the electrical or electronic system.

Classified by the dimensions of the relay

Relays can be classified based on their physical dimensions and form factors, which play a significant role in determining where and how they can be used. Here are some common classifications of relays based on their dimensions:

1. Miniature Relays:

- Miniature PCB Mount Relays: These relays are compact in size and designed for direct mounting on printed circuit boards (PCBs).

- Subminiature Relays: Even smaller than miniature relays, subminiature relays are used in applications where space is limited but electrical isolation is required.

2. Panel-Mount Relays:

- General-Purpose Panel-Mount Relays: These relays are designed to be mounted on panels or equipment surfaces for easy accessibility and maintenance.

- Power Panel-Mount Relays: Larger in size to accommodate higher current and voltage ratings, typically used for power distribution and control applications.

3. DIN Rail Relays:

- Industrial DIN Rail Mount Relays: Designed to be mounted on standard DIN rails commonly found in industrial control panels and equipment racks.

- Slim Profile DIN Rail Relays: Slimmer profile relays that save space on DIN rails while providing necessary switching capabilities.

4. Socket-Mount Relays:

- Socket-Mount PCB Relays: These relays are installed on relay sockets mounted on PCBs, allowing for easy replacement and maintenance.

- Socket-Mount Panel Relays: Relay sockets mounted on panels or equipment surfaces to facilitate quick relay changes without wiring adjustments.

5. Plug-In Relays:

- Ice Cube Relays: Compact plug-in relays that resemble an ice cube in shape, often used for general-purpose control applications.

- Octal Base Relays: Larger plug-in relays with an octal base, commonly used in industrial control and automation systems.

6. Slim Relays:

- Slim PCB Mount Relays: Thin and compact relays designed for applications with space constraints on PCBs.

- Slim Panel-Mount Relays: Slim-profile relays suitable for panel mounting in tight spaces.

7. Enclosed Relays:

- Sealed Enclosed Relays: Relays enclosed in protective casings for resistance against harsh environments, dust, and moisture.

- Open Frame Relays: Relays without protective covers, typically used in controlled environments where protection is not a primary concern.

8. Hermetically Sealed Relays:

- Relays that are completely sealed to prevent any contamination or exposure to external elements, maintaining reliability in challenging environments.

Selecting relays based on their dimensions is essential to ensure they fit within the available space and meet the mechanical requirements of the application. Proper consideration of the relay size and form factor helps in optimizing the layout and functionality of the electrical or electronic system.

Classified by the protection characteristics of the relay

Relays can also be classified based on their protection characteristics, which are essential for ensuring the reliability and safety of the electrical or electronic system where they are used. Here are some common classifications of relays based on their protection characteristics:

1. Overload Protection Relays:

- Thermal Overload Relays: These relays protect the system against excessive currents by tripping when the temperature rises above a specified threshold, typically due to overcurrent conditions.

2. Short Circuit Protection Relays:

- Instantaneous Tripping Relays: Designed to trip immediately when a short circuit occurs to prevent damage to the electrical system or equipment.

- Time-Delayed Tripping Relays: These relays provide a delay before tripping in response to short circuit conditions, allowing temporary overcurrents without triggering the protection mechanism.

3. Ground Fault Protection Relays:

- Ground Fault Relays: Detect ground faults or leakage currents to protect against electrical shocks and insulation damage, tripping the circuit when such faults are detected.

4. Voltage Monitoring Relays:

- Overvoltage Relays: Protect against excessive voltage levels that may damage equipment or components by disconnecting the circuit when overvoltage conditions occur.

- Undervoltage Relays: Trip the circuit when the voltage falls below a set threshold, preventing damage from insufficient voltage levels.

5. Reverse Polarity Protection Relays:

- Reverse Current Relays: Protect against reverse current flow in a circuit, preventing damage to sensitive components or ensuring proper operation of the system.

6. Phase Loss Protection Relays:

- Phase Loss Relays: Detect the loss of one or more phases in a three-phase system, preventing damage to motors and other equipment that rely on balanced three-phase power.

7. Thermal Protection Relays:

- Temperature-Compensated Relays: Adjust their operation based on ambient temperature changes to maintain accurate and reliable protection characteristics.

- Thermal Bi-Metal Relays: Use thermal expansion to trip when the temperature exceeds a predetermined level, safeguarding against overheating.

8. Arc Flash Protection Relays:

- Arc Flash Relay Systems: Detect and mitigate arc flash incidents by quickly disconnecting power when an arc flash is detected, protecting personnel and equipment.

Relays with built-in protection characteristics help enhance the safety and reliability of electrical systems by safeguarding against various electrical faults and abnormalities. Selecting relays with the appropriate protection features ensures efficient system operation and minimizes the risk of damage or accidents.